Pacific School of Engineering

Approved by AICTE,New Delhi and Affiliated to GTU,Ahmedabad

Degree Engineering | Diploma Studies

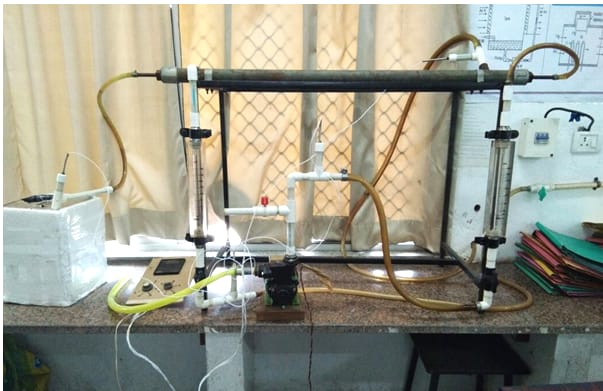

In heat exchanger, we are using conventional heat transfer fluid such as water, mineral oil and ethylene glycol. However, the heat transfer efficiency decrease because of their low thermal conductivities. It has been found that the heat transfer rates of these conventional fluid can be increased by suspension of metallic nanoparticles. The suspended metallic nanoparticles can change the heat transfer characteristics of the base fluid. To improve the heat transfer characteristic of double pipe heat exchanger, the various fins are installed on the outer surface of the inner tube and the level of turbulence increased and heat transfer characteristic of heat exchanger are increased.

Compressed Air Driven Engine (CADE) is an alternative technology which uses compressed air to run engine and thus eliminate the use of fossil fuel. This engine run only high pressure compressed air, the exhaust of which undoubtedly only air, making it is a zero pollution engine as well as the exhaust of air temperature may be equal to atmospheric temperature so thus help in controlling global warming. In CADE no heat generated because there is no combustion of fuel, hence this engine no need any cooling system. CADE is better option to produced power to run automobile vehicle, generator etc.

The engine was modified from 4-stroke to 2-stroke engine using a cam system which driven by crank shaft, and some another modification, it can driven by filter compressed air which pressure up to 9-10 bar. Operation cost of this engine is 6 to 7 time less than the fossil fuel.

Further, due to country's dwindling petroleum reserves and increased costly imports of petroleum, non-conventional energy resources are slowly gaining importance. The use of biogas using kitchen waste as feedstock can help solve the problem of energy deficit and at the same time, allow the safe disposal of kitchen waste which is often unscientifically dumped or discarded.

It is a need of the hour to investigate the existing technology for making it user-friendly, compact and economical. The problem is thoroughly studied and it is decided to develop the solution at college canteen by using kitchen waste (approximately 2kg to 10kg daily) and thus lower down the consumption of LPG cylinders. The kitchen waste generated has high calorific value and moisture content. The Floating drum Bio-gas plant is made at where further investigation is going on to develop the commercial product of biogas plant.

- Now a days the main problem in village agro areas shortage of electricity for agriculture and other purpose.To overcome this problem we choose this project to produce the electricity from the small canals.

- Our object is to extract the renewable energy from moving fluid from small canal. For extracting energy we are going to use cross flow turbine.

➢The main objective of this project is to design the various equipment of the steam system in such a way that the optimization of stream can be done.

➢ Also the component of the industry is ESP that uses to purify the hot exhaust gases before exiting the hot gases from chimney.

➢ So after completing the analysis of plant, start to think about of design procedure.

➢ Design the turbine component as required for electricity generation Recommendation as well as design the ESP.

In areas with very hot weather conditions (50 to 60℃), the temperature and pressure of the air-conditioning condenser are increased considerably. This causes a decrease in the cooling capacity of the cycle and also causes an increase in the power consumption due to increased pressure ratio. There are many methods used to increase the coefficient of performance of refrigeration and air conditioning systems. The most widely used methods involve sub-cooling of the refrigerant. Evaporative condensers are installed in cooling and refrigeration machines to reject heat and may be used with all types of compressors with high pressure refrigerants. The refrigerant-side modification includes adding a pair of Heat exchangers for exchanging heat between condenser exit and evaporator exit by using water-antifreeze mixture as a working fluid. A Water-Refrigerant evaporator has been designed, manufactured, and compared with original Air-Refrigerant evaporator performance.

|

Everywhere there is researches and funding going on for using hydrogen as core fuel for cars and vehicles but no one has though to use hydrogen as core fuel in homemade appliances. This can increase the efficiency and reduces the pollution. |

The aim of the project is to construct such a material handling device, which will be helpful to the material unload easily from traditional system, in traditional tipper system can unload the material from only one side (Rear side). Because of this time and fuel consumption is more, road blockage and also not easy for unload material in narrow space. So, for this three-way tipper system is unload the material.

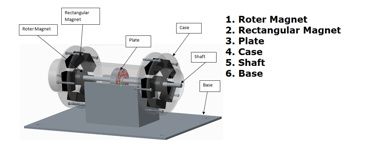

A Tesla turbine is bladeless centripetal flow type turbine. It is as well recognized as the boundary layer turbine, cohesion type turbine and Prandlt layer turbine because it is used boundary layer effect and not a fluid impinging upon the blades as in a convectional turbine. Tesla turbine has found wide ranging of application that includes the handling of a mixture of solid, liquid and viscous fluid without damaging the part. This project work is chiefly focused on implementation of magnetic bearing in Tesla turbine.