Pacific School of Engineering

Approved by AICTE,New Delhi and Affiliated to GTU,Ahmedabad

Integrated M.Sc. IT | Degree Engineering | Diploma Studies

Expert Name : Dr. Deborah Roasario

Audience : Final and Pre-final year Student

On February 22nd, 2024, the Chemical Engineering Department of Pacific School of Engineering, under the IIChE-ARC banner, hosted a seminar titled "Higher Education Opportunities in the USA." for final year and pre-final year students. The esteemed speaker for the event was Dr. Deborah Roasario, a Senior Advisor at EducationUSA and an Oxford University alumna.

View Detail Report

Expert Name : Dr. Dhiren Desai

Audians : Final and Pre-Final Year Student

On 9th June, 2023 the Chemical Engineering Department of Pacific School of Engineering, hosted an expert talk on psychology of mental stress. Dr. Dhiren Desai (Medical Practitioner) who delivered an inspiring address.

Dr. Desai’s speech focused on the psychology of mental stress, offering valuable insights on how to navigate difficult phases and cultivate self-motivation. His kind words and extensive knowledge provided attendees with practical strategies to alleviate mental stress and stay motivated even during challenging times. The event successfully achieved its aim of appreciating students’ accomplishment while imparting valuable wisdom to help them thrive.

Expert Name : Dharmendra Kashyap

Audians : All Faculty Member and Students

Fire Safety lecture and demonstration was delivered on 3rd January, 2023. A workshop is conducted on fire extinguishers at A-building for Staff member, Lab Technicians and office Assistants, etc. The following points were discussed, and Mock drill also conducted to create awareness to all of the attendees and discussed different kinds of fire and the causes of their occurrences and how to use fire extinguishers, how many types of extinguishers we are using in our campus explained by the Dharmendra sir.

View Detail Report

Expert Name : Dr. Bhavin Desai, Er. Anubhav Pathak

Audians : Final Year students of Chemical Engineering

Fertilizers play a major part in agriculture in terms of helping supply the constantly growing global population with foodstuffs. A fertilizer is a chemical or natural substance added to soil or land to increase its fertility. The purpose of fertilizers are to supplement the natural supply of soil nutrient, build up soil fertility in order to satisfy the demand of crops with a high yield potential and to compensate for the nutrients taken by harvested products or lost by unavoidable leakages to the environment, in order to maintain good soil conditions for cropping. The discussion was elaborated to types of fertilizers, different contents in fertilizers and its uses.

View Detail Report

Expert Name : Mr. Gautam Pradhan

Audians : Students of Chemical Engineering Department

Broadening the capabilities of chemical engineers everywhere with enhanced process simulation software, CHEMCAD is designed to help you drive productivity, accomplish day-to-day tasks, and tackle the toughest chemical process models.

Expert Name : Prof. Ashish modi

Audians : Undergraduate Students and Industrial Person

Nanotechnology is the engineering of functional systems at the molecular scale. This covers both current work and concepts that are more advanced. In its original sense, nanotechnology refers to the projected ability to construct items from the bottom up, using techniques and tools being developed today to make complete, high performance products.

Expert Name : Mr. Parth Desai

Audians : Undergraduate Students and Industrial Person

Distillation is the most widely-used method of separating fluid mixtures on a commercial scale; it is thus an important part of many processes in the oil and chemical industries. The advantages of distillation are high purity products; economies of scale; well-established technology and competitive supply of equipment; use of low temperature, low cost energy; well suited for energy integration into the surrounding process.

Expert Name : Prof. B. A. Domadia

Audians : Undergraduate Students and Industrial Person

A unit operation is a basic step in process industries. Unit operations involve a physical change or chemical transformation such as distillation, fluid transportation, heat and mass transfer, evaporation, extraction, drying, crystallization, filtration, mixing, size separation, crushing and grinding, and conveying.

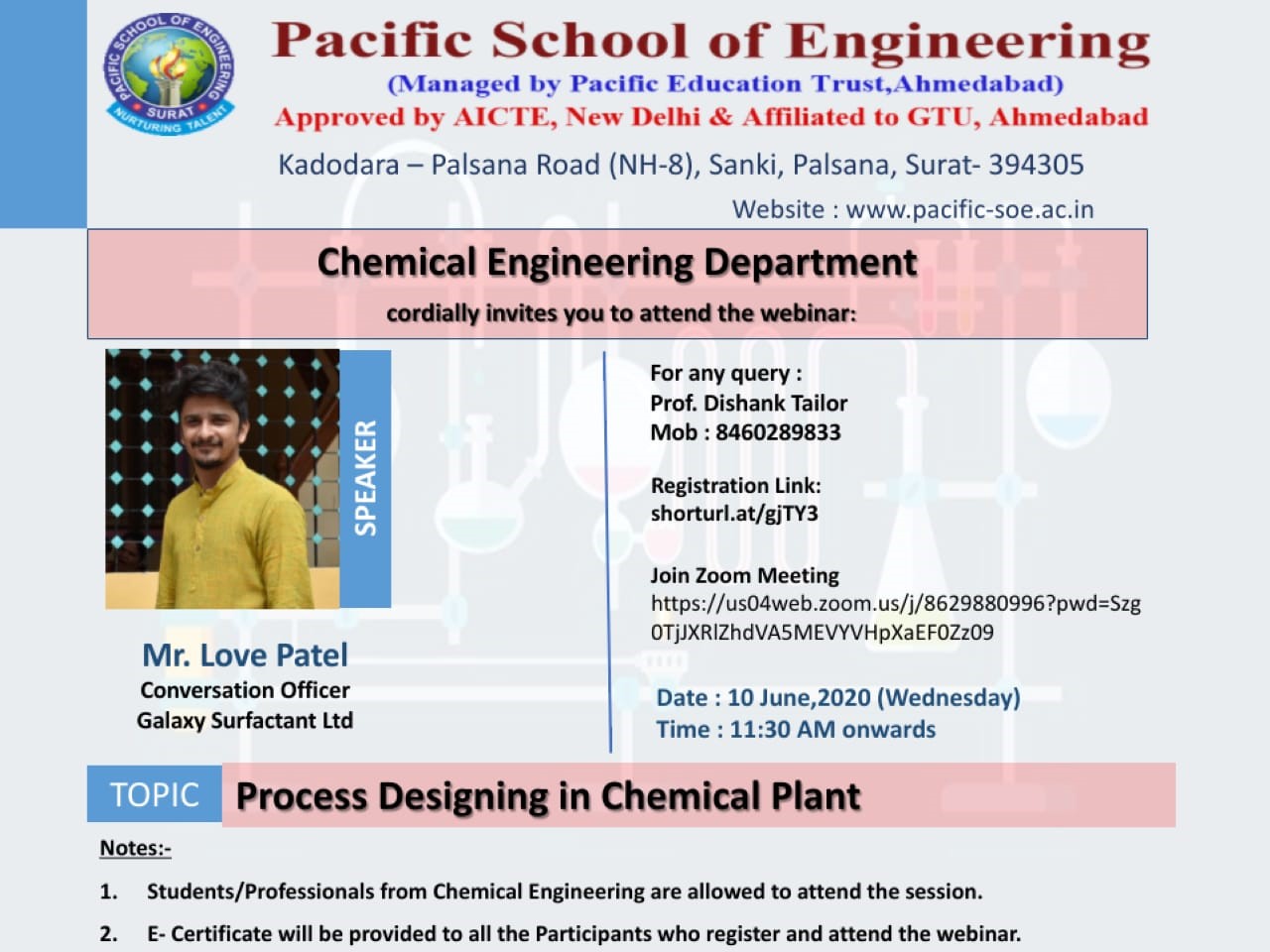

Expert Name : Mr. Love Patel

Audians : Undergraduate Students and Industrial Person

Process design is the choice and sequencing of units for desired physical and/or chemical transformation of materials. Process design is central to chemical engineering, and it can be considered to be the summit of that field, bringing together all of the field's components.

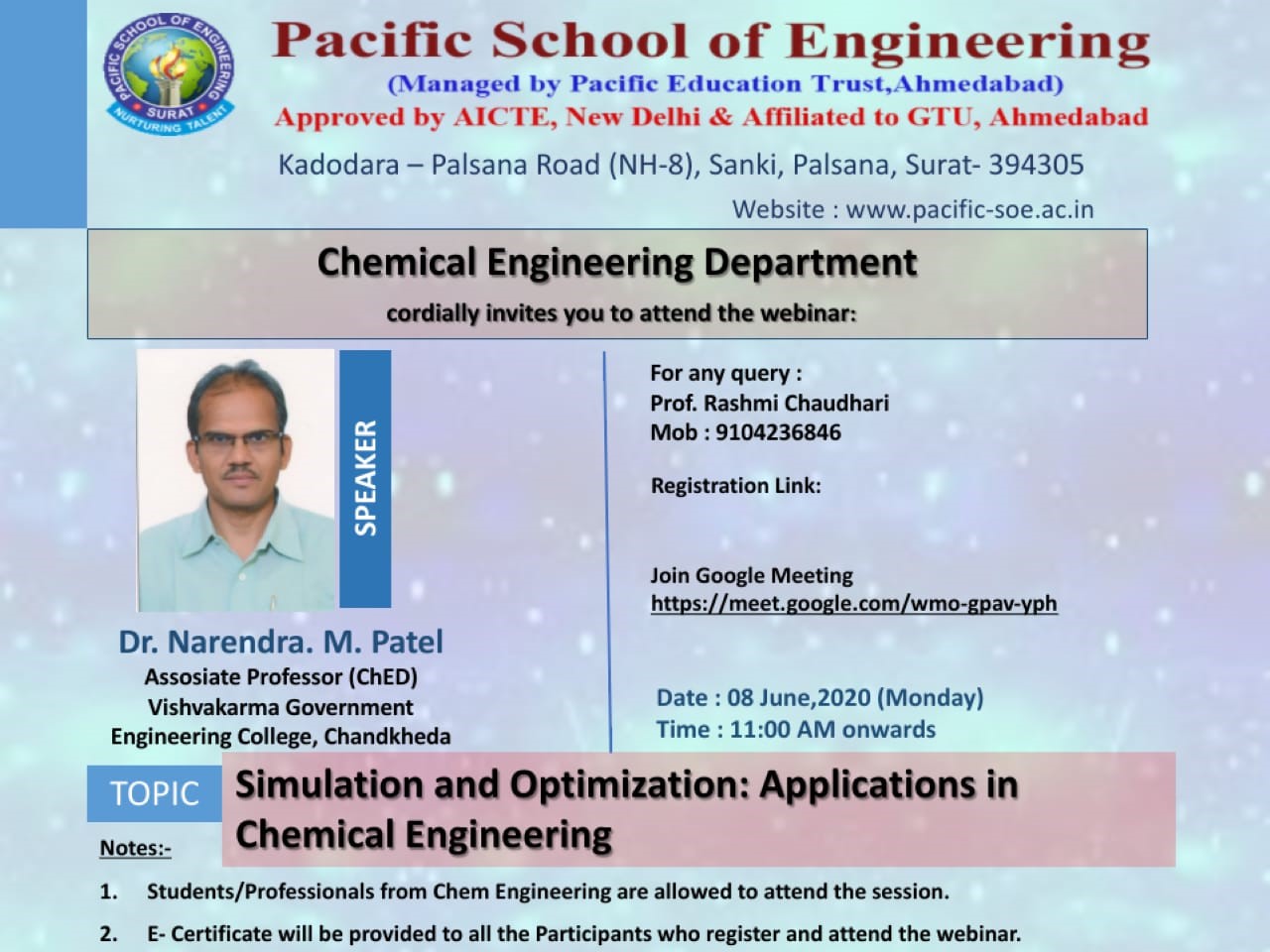

Expert Name : Dr. N. M. Patel

Audians : Undergraduate Students and Industrial Person

Process simulation is a model-based representation of chemical, physical, biological, and other technical processes and unit operations in software. Basic prerequisites for the model are chemical and physical properties of pure components and mixtures, of reactions, and of mathematical models which, in combination, allow the calculation of process properties by the software.

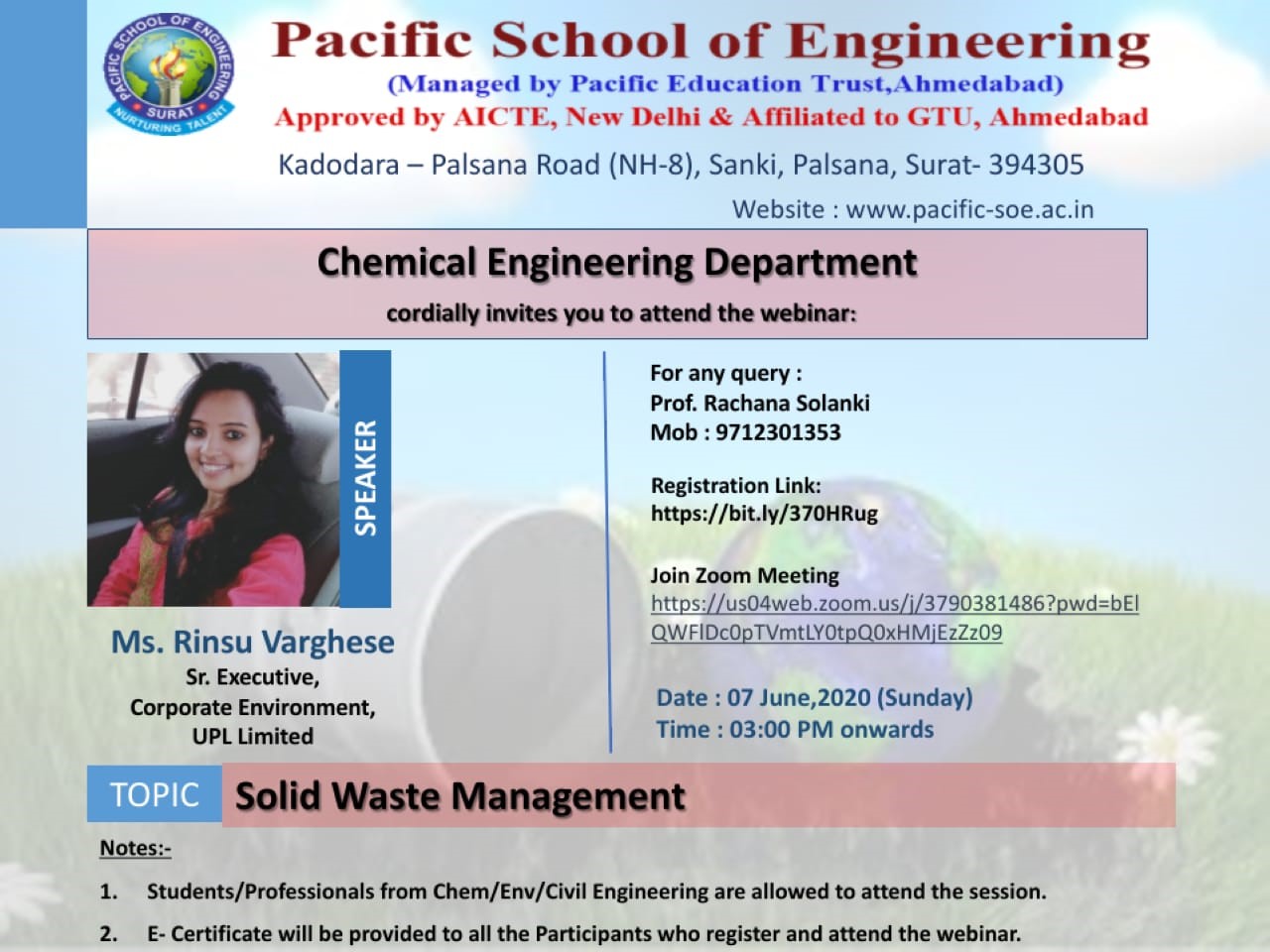

Expert Name : Ms. Rinsu Varghese

Audians : Undergraduate Students and Industrial Person

Solid-waste management; the collecting, treating, and disposing of solid material that is discarded because it has served its purpose or is no longer useful. Waste management is all about how solid waste can be changed and used as a valuable resource.

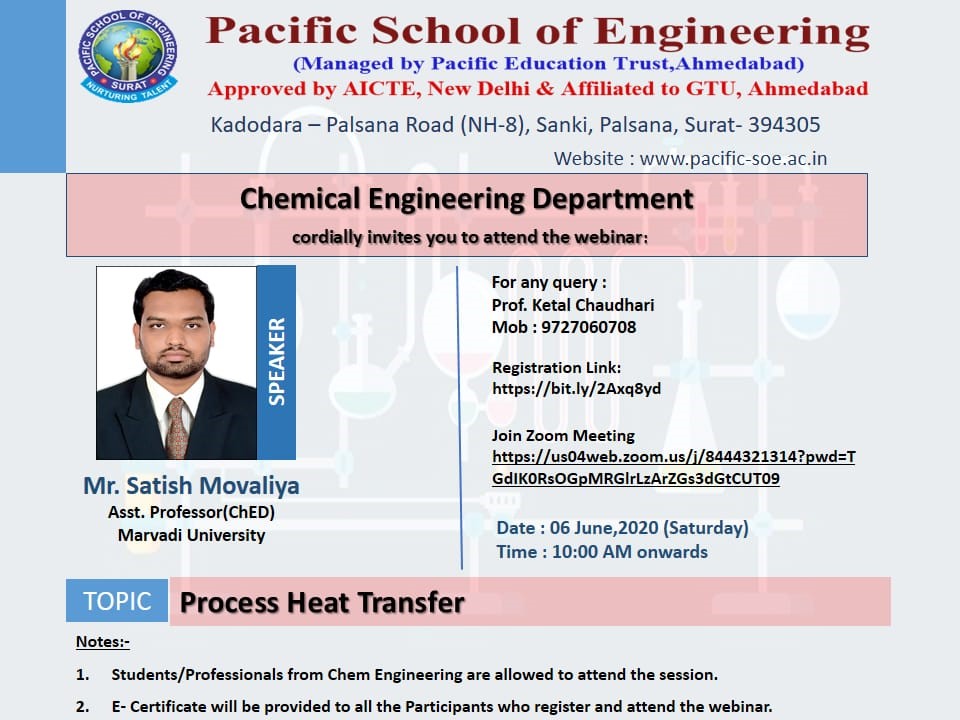

Expert Name : Prof. Satish Movaliya

Audians : Undergraduate Students and Industrial Person

Process Heat Transfer is a reference on the design and implementation of industrial heat transfer equipments; heat exchanger, evaporator, boiler, etc.. It provides the background needed to understand used by professional engineers in the design and analysis of heat exchangers and the related equipments.

Expert Name : Mr. Nutan Paliwal (Executive Engineer, ONGC Hazira)

Audians : All 8th & 6th Semester students of Chemical Engineering Department.

The students were made familiar with the sweetening process of crude in which sour gas containing significant amounts of hydrogen sulfide (H2S), Carbon Dioxide (CO2) are removed through different techniques. The processing sequence of Natural Gas Liquids (NGL) extraction, fractionation, and treatment to separating ethane, propane, butane, naphtha, ATF, SOK, Diesel, Kerosene, etc were explained.

View Detail Report

Expert Name : Prof. Ashish Modi

Audians : All 6th & 4th Semester students of Chemical Engineering Department

The term pervaporation is derived from the two steps of the process, permeation through the membrane by the permeate, then its evaporation into the vapor phase. This process is used by a number of industries for several different processes, including purification and analysis, due to its simplicity and in-line nature. The membrane acts as a selective barrier between the two phases: the liquid-phase feed and the vapor-phase permeate. It allows the desired component(s) of the liquid feed to transfer through it by vaporization. Separation of components is based on a difference in transport rate of individual components through the membrane.

View Detail Report

Expert Name : Prof. Suchen B.Thakore

Audians : All 8th and 6th Semester students of Chemical Engg. Department

Batch processes play a very significant role in the chemical process industry. Because of their great flexibility, they are extensively used in the production of fine and specialty chemicals, Pharmaceuticals, Polymers, and bio- products, as well as other products for which efficient and continuous production is not feasible. Thus, batch processes contribute to a significant proportion in the world’s chemical production (especially in value). They are used for liquid phase reaction that requires fairly long reaction time. The batch reactors are used for beverage processes. The increasing technological trends towards the manufacturing of specialty chemicals make the efficient design and operation of batch processes even more important.

View Detail Report

Expert Name : Devesh Sharma, Madhur Vachchani, Pragnesh Sindha

Audians : All 8th Semester students of Chemical Engineering Department

Modeling and simulation are extremely important tools in chemical Engineering. DWSIM is

an open source chemical process simulator. It features a Graphical User Interface, advanced

thermodynamics calculations, reaction support and petroleum characterization / hypothetical

component generation tools. DWSIM can simulate steady-state, vapor-liquid, vapor-liquidliquid,

solid-liquid and aqueous electrolyte equilibrium processes and has been built in

thermodynamic models and unit operations.

Expert Name : Mr. Bhavin Shah

Audians : 6 & 8 semester students

The expert lecture was organized regarding the basic details about the distillation column. Mr. Bhavin Shah, from Essar Oil Ltd., Jamnagar, deputy manager of the company was invited for the lecture. The operation of distillation column, types of trays, its efficiency all basic details were provided in this session. In short, the lecture was very knowledgeable.

View Detail Report